CLEARFIELD – The latest Lock Haven University Clearfield Campus Speaker session was a geologist’s view on Marcellus Shale. The speaker was Professor Tristan Ashcroft from Lock Haven.

Ashcroft had been working in Nevada for a few years on his doctorate. When he left the area Marcellus Shale was known, but it wasn’t that large of a deal. He returned to find what had been, as he described, a little blurb in a newspaper to be a controversial subject related to his field of study. Finding himself bombarded with questions, Ashcroft began looking into the subject as a geologist.

The presentation was a neutral outlaying of Marcellus Shale drilling process, the history of why the shale exists, a look at the economics factors and the environmental factors revolving around the subject.

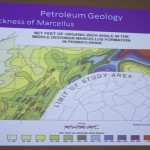

The reason the shale deposit exists is due to ancient tectonic movements. Pre-dating Pangea, what is now the portions of the North East where Marcellus Shale can be found were once the bottom of a sea similar to the modern day Mediterranean. This closed off basin of water was lacking oxygen levels to promote decay of dead biological matter so deposits of biomass accumulated on the basin floor. Millions of years, pressure and heat turned this dead biomass into fossil fuels as the basin was gradually filled in due to erosion.

According to Ashcroft, due to the age of when the biomass was laid down it is deeper than the well water aquifers, beneath large deposits of non-Marcellus Shale, beneath a layer of lime that is believed to act as a seal, rests above another lime layer that, and that layer rests above some other deposits before reaching the deep level aquifers. The depth of Marcellus Shale was given as a major difference between the local natural gas and the gas extracted from the Barnett Shale in Texas when the latter was brought up for comparison in the question in answers.

The drilling process as described by Ashcroft is that directional drilling used to reach a range of natural gas around the well was invented back in the 1920s. The hydraulic fracturing used to retrieve the natural gas from the shale was developed in the 1960s. Each well has a total length of line it can reach between vertical and horizontal differences. The shallower the well the father it can reach out horizontally. Where the well has to drill down deeper there is less length to allow for horizontal drilling.

Fracturing involves creating high pressure to open up the cracks and depositing sand or other substances to keep the cracks open. The fracturing pressure pushes most, half according to Ashcroft, of the natural gas the well will produce over its lifetime through the line within the first six to twelve months of its life. As the pressure drops the flow will reduce over years to decades.

The hydraulic fluid contains chemicals to help the drilling process. The pipe is cased in cement to prevent leaking, but the casing process also covers the entry points into the pipe for the natural gas. The entry points are forcibly opened and acid is added to the hydraulic fluid to prevent any cement entering and clogging the opened pipeline. Lubricants are added for the sand and other wedge materials so the pipe doesn’t get clogged.

With the fracturing fluid minerals and other substances are picked up and carried out of the well. This is where the heavy metals and radioactive elements of fracturing water come into play. It also contains brine.

Methods of dealing with the fracturing water have improved, said Ashcroft.

Early on, older water treatment plants couldn’t properly treat the water. Newer plants have the capability if they are prepared for it. Ashcroft didn’t state what qualified a plant as older or new. He did state that there has been strides in having fracturing fluid become a reusable substance. This would lead to less new water needed for drilling and less fracturing water to be treated afterwards.

The clearing of some forested areas for pipelines and well pads will have a positive and negative effect on wildlife. Wildlife that requires continuous forest land will be negatively impacted. Wildlife that does well with breaks in the forest, such as deer, will likely react positively to the newly opened up land.

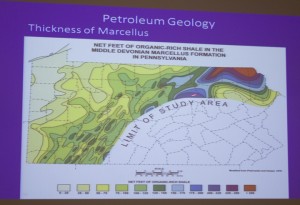

Wells in Pennsylvania are currently located in two hot spots. The south west where the first drilling took place and the North East Pennsylvania where the deposits are the thickest.

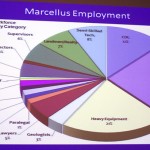

Economically, Ashcroft states that the industry will lead to 8-12 thousand jobs between direct and indirect means. Behind each worker at the drill site you need truckers for the fracturing water transport, welders for the metal work, people for the clerical work, lawyers and other jobs. Twenty percent of the created jobs were filled by Pennsylvanians in 2010.

“The industry has stated they want to change these numbers,” said Ashcroft.

He stated that the prime motivation being the desire to not pay to have workers travel across the country and live in hotel rooms. Drilling could lead to death if not done properly, according to Ashcroft pointing out thousands of PSI are involved, and currently there aren’t many Pennsylvanians trained for this type of work.

Ashcroft advised looking at cost-benefit analysis for individuals interested in what drilling will bring to the area. According to him, economic impact studies look primarily at the benefit only. Costs include treating fracturing water, road infrastructure repair, the economic impact of less environmental impact, etc.

“It is going to be treated by somebody,” said Ashcroft.

A guest pointed out that the natural gas may not be used here in the United States, let alone Pennsylvania. Instead it could easily be shipped overseas instead of being used to reduce dependence on foreign energy sources. Ashcroft pointed out that any natural gas heading to foreign countries would be bringing in money from those countries to pay for it.