This guide to the key differences between polyurethane and rubber will help you determine which material is best suited to your application.

Polyurethane and rubber are both highly popular types of elastomers used in the manufacturing industry. While they have several similar qualities, such as their high degree of flexibility, durability, and resilience, the two materials are far from synonymous. If you’re trying to determine which material will best suit your application, consult this guide on the key differences between polyurethane and rubber.

Degree of Durability

Although both polyurethane and rubber boast a high degree of durability, the former is typically the more resilient of the two. Polyurethane generally lasts longer than rubber in the presence of stress and can better withstand constant stretching due to its carbamate links.

In addition, polyurethane also has high abrasion and tear resistance. As such, it is an ideal choice for applications that require prolonged exposure to harsh environments, high amounts of pressure, or stretching that would ultimately cause rubber to degrade at a faster pace.

Vibration and Noise Absorption

In applications where you need to reduce sound and vibrations, rubber will generally prove most advantageous. While polyurethane also serves as an effective absorber of energy, the softness of rubber typically makes it more adept at absorbing vibrations and noise. Thus, rubber is generally an ideal choice for the production of anti-vibration or noise-dampening products.

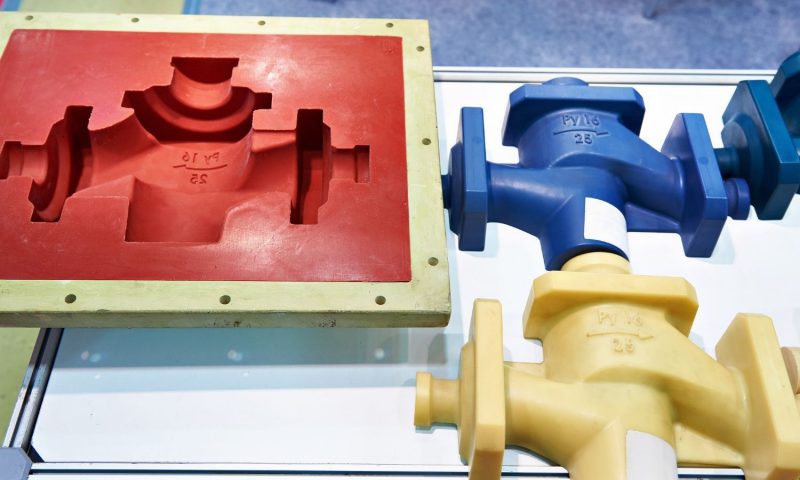

Ease of Production

Another one of the key differences between polyurethane and rubberis their ease of production. Ultimately, polyurethane parts are much easier and more cost-effective to produce. One of the most popular ways to create polyurethane parts is through the process of reaction injection molding.

During this process, two liquids—polylol and isocyanate—combine and get injected into a tool. Since the materials have such a low viscosity, they easily fill out every nook and cranny of the mold in a matter of seconds without requiring high temperatures or pressures. Thus, the process of creating polyurethane parts is far more efficient and budget-friendly.