Allegheny Health Network, Highmark Health volunteers will produce tens of thousands of specimen collection kits at Highmark Health’s Downtown Pittsburgh headquarters

PITTSBURGH – Faced with a national shortage of COVID-19 test kits, Allegheny Health Network (AHN) in Pittsburgh has come up with a simple but innovative solution – making thousands of its own.

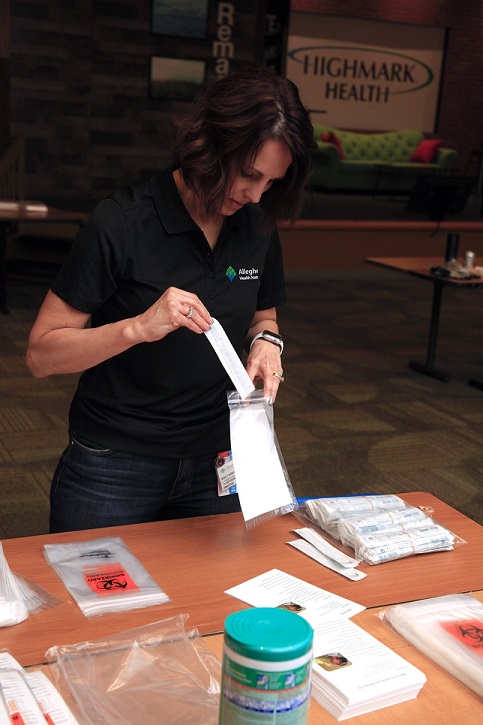

On Thursday, about 15 AHN employees volunteered to assemble specimen collection kits, for use at AHN hospitals and its drive-up COVID-19 collection sites around Western Pennsylvania.

“The work that we’re doing today is mission-critical to limiting the spread of the novel coronavirus and flattening the COVID-19 curve in this region,” said Kelly Glass, AHN’s vice president of strategy, operations, and shared services.

Typically, COVID-19 specimen kits, much like influenza test kits, come fully assembled from a vendor. The kits that AHN uses include two biohazard bags, labels, a naso-pharyngeal swab, an instruction sheet, and a tube containing viral transport media, so the collected sample can be tested later.

Those vendor-supplied kits have been difficult to obtain, thanks to national shortages of swabs, transport media, and other components. In response, AHN and its parent company, Pittsburgh-based Highmark Health, developed a plan over the last week to source or create individual test kit components, allowing the kits to be assembled in-house.

Naso-pharyngeal swabs, for example, were harvested from AHN’s existing stock of flu test kits. Labels and instruction sheets were printed by Highmark Health’s in-house print shop. The transport media inside the sample tubes is being manufactured to CDC specifications by the AHN Research Institute.

Those individual components were collected and sorted earlier this week. Beginning Thursday, the volunteer group assembled those components into about 6,000 kits, and over the next few weeks, a rotating group of volunteers will assemble tens of thousands more, to meet testing demand across the network.

AHN will continue to procure fully-assembled COVID-19 kits from external vendors, and currently has enough vendor-supplied kits to meet existing patient need. But producing additional kits in-house protects the network against future supply-chain interruptions, or shortages driven by a local COVID-19 case surge.

“This remarkable display of ingenuity is the result of an incredible team effort, within AHN and across the entire Highmark Health enterprise,” said Dr. Brian Parker, AHN’s Chief Quality Officer. “It’s another example of how the collaboration between our organizations allows us to better serve our patients, and the health of the entire region.”

The makeshift assembly line is being housed in an auditorium at Highmark Health’s Downtown Pittsburgh headquarters. Work stations were positioned at least 10 feet apart, in order to maintain social distancing. Employee volunteers included clinical staff, back-office employees, and senior leaders.

“Our volunteers are ensuring that AHN’s clinical employees are equipped with the kits they need, when they need them, today and in the weeks ahead,” Glass said.

“We are directly supporting the health of our community and the safety of our front-line caregivers – and we are indirectly supporting the entire health care community by doing our part to relieve this ongoing specimen kit shortage.”