That is a question Penn State faculty are looking at as part of a research project the National Energy Technology Lab’s Regional University Alliance is conducting.

Seth Blumsack, John T. Ryan Jr. Faculty Fellow, andhttp://www.eme.psu.edu/faculty/ertekinTurgay Ertekin, head, Department of Energy and Mineral Engineering, and holds the George E. Trimble Chair in Earth and Mineral Sciences, are part of the group studying whether it would be possible and make economic sense to capture carbon dioxide produced at large point sources and pump it into existing natural gas wells.

“It’s driven by the potential social problem of managing carbon dioxide emissions,” said Blumsack, who is also a faculty affiliate in Penn State’s Earth and Environmental Systems Institute.

“The big boys like power generating plants and transportation get a lot of press,” Blumsack said. “But, heavy industry is a substantial contributor to global carbon dioxide emissions. The annual emissions from a really big facility, like a steel mill or cement plant, can rival the annual carbon dioxide emissions from a moderately-sized coal-fired power plant.”

The study, the first of its kind, is also looking at what is known as enhanced gas production — injecting carbon dioxide into the wells and stimulating more gas production. That scenario would mean separating the two gases, then pushing the carbon dioxide back into the formation, potentially reaping the economic benefit of the additional gas production — depending on its market price.

“What we are trying to do is develop and analyze the protocols to help us really understand the efficiency of sequestering carbon dioxide in shale reservoirs,” Ertekin said. “These reservoirs have been holding a different gas for millions of years in a secure way. They may turn out to be a dependable repository for us to sequester carbon dioxide in a secure way.”

While using old oil and gas wells to store waste fluids, including those from hydraulic fracturing, has a long history, using those wells for carbon dioxide storage is new territory. Similarly, U.S. Environmental Protection Agency regulations covering carbon dioxide sequestration were designed with underground saline aquifers, not former natural gas drilling sites, in mind.

If feasible, the initiative would mean that rather than decommissioning gas wells after production tails off, the wells could be recommissioned. The study, being done with scientists from West Virginia University and the U.S. Department of Energy’s National Energy Technology Laboratory, started in fall 2011 and is expected to be completed in November 2013. It is expected to provide technical guidance and economic analysis, particularly if comprehensive greenhouse gas emissions regulations are enacted in the United States.

For the study, Ertekin and others on the team are building mathematical models of how shale gas reservoirs, specifically those in Pennsylvania, would react to having large volumes of carbon dioxide injected into them at high pressure. They hope to answer questions such as: What would that do to the fractures? How will the adsorption work?

“If we sequester carbon dioxide, we have to make sure it’s long-term and will stay there in a secure way,” Ertekin said. “In these types of reservoirs, which have a relatively large depth and have stored gases for a long period of time, we expect they will be able to secure it in large volumes.”

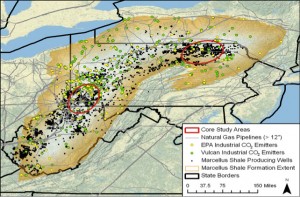

Blumsack is studying the feasibility of building a transportation network that could capture the carbon dioxide at the sources — such as chemical plants and paper mills — and transport it to the wells where it would be injected and stored. A key part of that is whether the project would be economically viable.

So far, he said, the cost of transportation, appears to be “fairly modest” — on the order of a few to several dollars per ton of carbon dioxide.

“You can decrease these costs substantially if you can coordinate transportation with multiple industrial sources and multiple injection sites,” he said. “If each plant makes its own decision about managing carbon dioxide, the costs will be much higher than if the problem is approached collectively.”

Similarly, the study includes a cost analysis of when obtaining additional gas by capturing and separating the methane and carbon dioxide that come back out would make economic sense.

“If the natural gas that’s produced is low, then it’s not worth it and the well is capped,” Blumsack said. “But, with the price of natural gas going up, at some point it is worth it.”

Another major cost will be the long-term monitoring of the sites.

Ertekin noted that small-scale pilot studies would be the next step “once we find the answers to the scientific and engineering questions for this type of system.”